Specialized in making Pneumatic Conveying System, Bag Dumping Station, Recipe Mixer, etc..

About

Us

Prasad Group was founded in 1984 and is headquartered in

Ahmedabad. It is a major player in the pneumatic conveying business,

with a yearly output of over 2,000 units, 1,00,000 m2 floor area, and

products exported all over the world. Its long-term promises to all

committed consumers include providing high-quality products and great

technical services.

In addition, our group company has a

pan-India sales and service network. This company is a well-known and

trusted brand, which customers prefer to get the right value for their

money.

Our

Group Company: Quality Focused

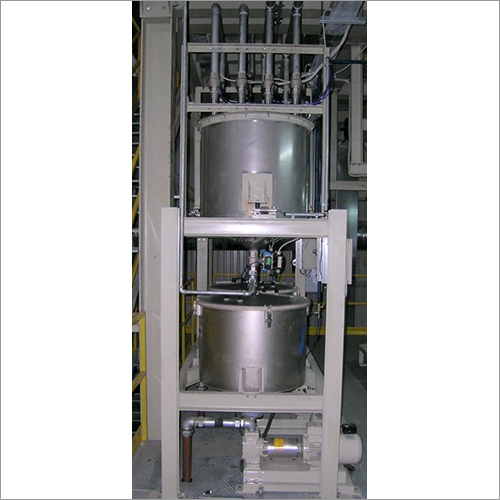

Our company, Pneucon

Solids Automation LLP, is a technically advanced company that is

serving customers with a wide range of products. As a manufacturer

and supplier, we are meeting the needs of customers associated with

Pneumatic Conveying, Unloading, Storage, Batching, Micro Dosing,

Distributor, Shifting, Screening, Liquid Handling and a lot more

products. The features such as efficiency, low maintenance, easy

installation, user-friendliness, etc., have made our products the

talk of the town. With the progression in the technology, we try to

improvise our array so that we can continue to amaze customers and

deliver them the worth of their money. We are an ideal match that

clients can ever choose to get the world-class products at reasonable

rates.

We are India's first

conveying equipment manufacturer to receive ISO 9001:2000 quality &

CE certification. The quality is maintained by a highly qualified

team & Process establishment.

Applications

|

|

Philosophy

Our

philosophy is to generate economy through automation. We believe

that, when automation is implemented in the production, then it

slashes down the conversion cost.

Vision

By

supplying machinery and equipment with futuristic and world-class

technology at reasonable rates, we are assisting the food,

pharmaceutical, and plastic industries in achieving the highest

levels of quality, productivity, and cost-efficiency.

Quality

Policy

To first understand our customer's needs, and then

to produce a solution that meets customer expectations.

People

Manpower

is the company's greatest source of strength and encouragement.

Design innovation, client happiness and operational excellence are

all priorities for the company dedicated and competent

personnel.

Mile Stones

1984-93

- For Klockner Windsor India Ltd., we started manufacturing plastic auxiliary and post extrusion equipment

- Produced monolayer film plant PP500 and PP750 (Polypropylene and HM) for the mentioned company.

- Produced nitride injection moulding machines and screws for extrusion.

1994-98

- In the year1995, we did a technical collaboration with Koch-Technik, Germany for manufacturing plastic auxiliary equipment like mixing, dosing, conveying and drying systems.

- We entered into a joint venture with Koch-Technik, Germany in the year 1996.

- In 1998, we tied a knot with GWK, Germany to manufacture mould temperature controller and chiller

- With Moditec, France, we did a technical collaboration in the year 1998 to develop a low-speed, high torque granulator, Goliath.

- The company was the first in India to receive ISO 9001:2000 quality certification for plastic auxiliary equipment.

- At Visteon Automotive (A division of Ford Motors India Ltd., Chennai), we did the 1st largest installation of the central chilling system.

1999-03

- Essel Packaging Ltd., Wada, received the first central conveying system from us.

- Moved to a new facility with a total space of 15,840 square meters.

- Balmer Lawrie-Vann Leer Ltd., Mumbai, received the first high-tech 'Goliath' twin granulator.

- Establishment of a new GWK plant with a sophisticated insulated manufacturing and prefabricated structure.

2004-08

- Technical collaboration with Crizaf, Italy (in 2005).

- In 2006, the company formed a joint venture with Wemo Automation AB of Sweden to manufacture robots for the plastics industry.

- Rapid Granulators AB, Swedon, with whom we collaborated on technical issues in 2007.

- At Havells India Ltd., Baddi, we put the first robot on an injection moulding machine.

- Technical collaboration with Ariostea, Italy (in 2008) to build bulk material handling systems, powder conveying systems and PVC.

2009

- Exclusive Equipment Manufacturing for Powder Material Pneumatic Conveying Began.

- Dedicated an advanced production facility for Pneumatic conveying System.

2011

- Corn starch conveying system with the ability to produce 2 tons/hour was installed.

- Country largest soft PVC handling solution have the ability to produce 5 tons/hour was installed.

2013

- 3 ton/hour pharmaceutical conveying system installed.

- Emerged India's largest polymer granule handling conveying solution entity.

2015

- For sales, marketing, and finance, a new green office building was constructed.

2016

- With a carpet area of 1,00,000 sqm, it became Asia's largest automated factory.

- In the European continent, the first make-in-India system for comprehensive powder material handling was installed by us.

2017

- In the handling and conveying of powder commodities, we became India's largest enterprise.

2018

- Started exclusive production facility for pneumatic conveying solution for food & pharmaceuticals industry.

- Supplied complete solution for 2 TPH maida & sooji handling with blending, batching and pasta line.

2019

- Complete solution for 2 TPH maida handling with silo storage was provided.

2020

- Food Pneumatic Conveying Solutions have been exported to Africa, the United States, and Europe.

- In Africa largest rice mill, a 4 ton/hour rice conveying system was installed.

Our

Research Lab: Where Nothing is Impossible

Novel

materials with higher dispersion are being developed as the industry

progresses. It means we are working with smaller particles that are

more cohesive. No plant manager would test the system on its own to

see if it works. We have invested in a cutting-edge Pneucon lab with

a variety of pipe sizes and conveying distances for a variety of

customer outputs. No project leaves the factory without extensive

testing to mimic clients plants conditions.

- Conveying distances that ranges from 15 to 120 meters.

- Pipe diameters ranging from 60 to 125 mm

- Output ranges from 100 kg/hr to 15 ton/hr.

- All trials are possible, including weighing, dosing, conveying and mixing.

- Monitoring in real-time on the testing server

Customers

can send us a sample for testing. We will run it on our pilot plant

and provide them with a complimentary test report.

Testing

Report by Our Lab

We are committed to

running your item in our testing facility in your presence at any

moment because we have live testing set up.

Infrastructure:

Our Plant

The state-of-the-art production

plant in Ahmedabad has a total area of 1,00,000 m2. Modern

infrastructure and technologically advanced machinery that satisfy

quality standards are available. Our group uses cutting-edge

techniques and systems to create the best products in the industry.

At our premises, we have divisions like assembly shop, chilling shop,

dispatch shop, fabrication shop, machinery shop, machining shop,

marketing office, production shop, research lab, testing shop,

etc.

Facilities

To

produce world-class products and services, we have a cutting-edge

production plant backed up by an ultra-modern R&D and training

centre. We are primarily undertaking component fabrication in-house

because we have this infrastructure for all of our group firms. New

Manufacturing Technology includes CNC Cutting, Laser Cutting, CNC

Multi Axis, Robotic Welding, Robotic Handling Tools, Short Blasting,

Roller Bending, Painting Facility, Plasma Cutting, Glass Blasting,

etc. We have facilities like:

|

|

We Care

We a socially responsible company that in collaboration with various NGOs, it has institutionalized CSR policies and conducted efforts in several areas of Gujarat and Bihar. We have contributed in the fields of environment, community support, education and many more. Our corporate responsibility initiatives includes projects of leveling, nursery, assistance for business, building check dams, mass marriage, midwifery training, primary education, vocational training, home for homeless, etc.

Our Group Companies

|

Plastic Auxiliary Equipment Division |

Textile Machinery Division |

Vaccum Pump Division |

|

|

|